Warning: Sad ending

After a five-year wait, an HP-IB plotter finally came within reach. Mike at the ARC Group had got it as part of a job lot, and he generously gave it to me.

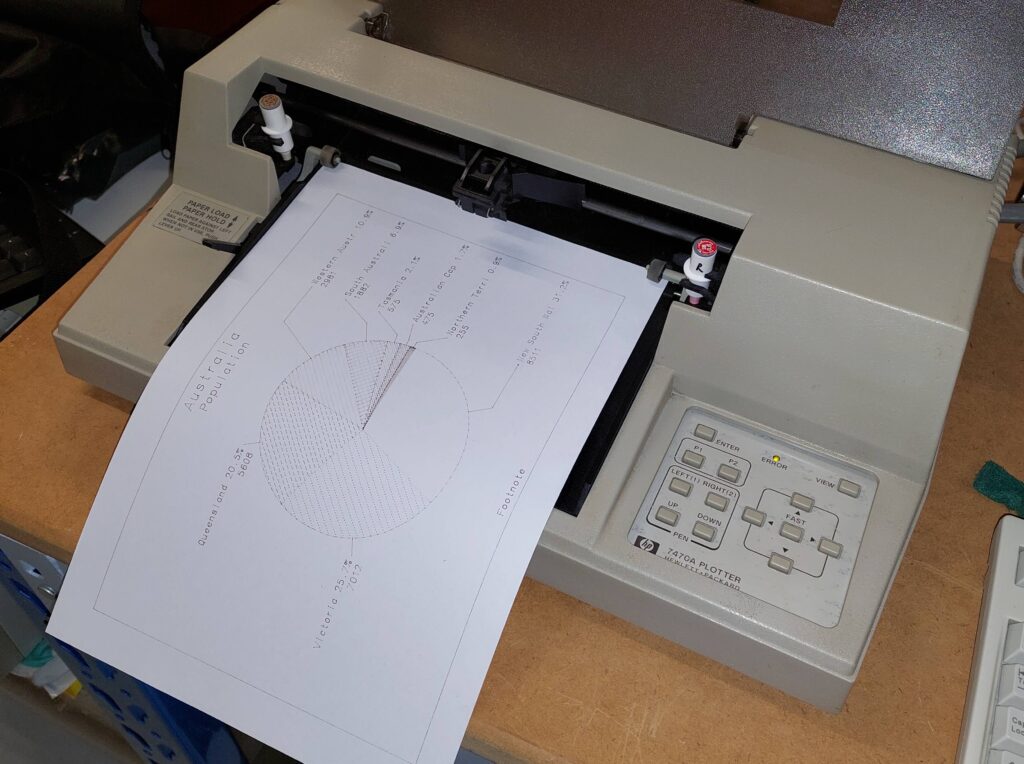

This is my second HP 7470A plotter – the other is the serial version. These plotters are very simple, two pen, paper-moving plotters. The serial interface supports operation with computers from many different manufacturers, whereas HP-IB is the native interface for the HP computers of the era.

There was just one problem with the new arrival: it had seen some weather.

With power off, the carriage would not budge and the papers wheels were similarly stuck fast. The carriage guide bar was quite corroded.

I could also see that some of the grip had come off the paper wheels and that the opposing rubber wheels had flat spots.

The machine was pretty filthy, so a full tear down seemed appropriate. I couldn’t find a service manual, so i used the force. I took a lot of photos as i pulled it apart.

One screw to release the carriage motor. It was still spinning freely, which was a good sign. The belt tensioner and wheel came loose at this point. They were put safely in a container with the spring.

With the carriage motor out of the way, the up/down solenoid mounting screw can be backed off and the pen up/down bar can be removed. The rubber belt can then be removed.

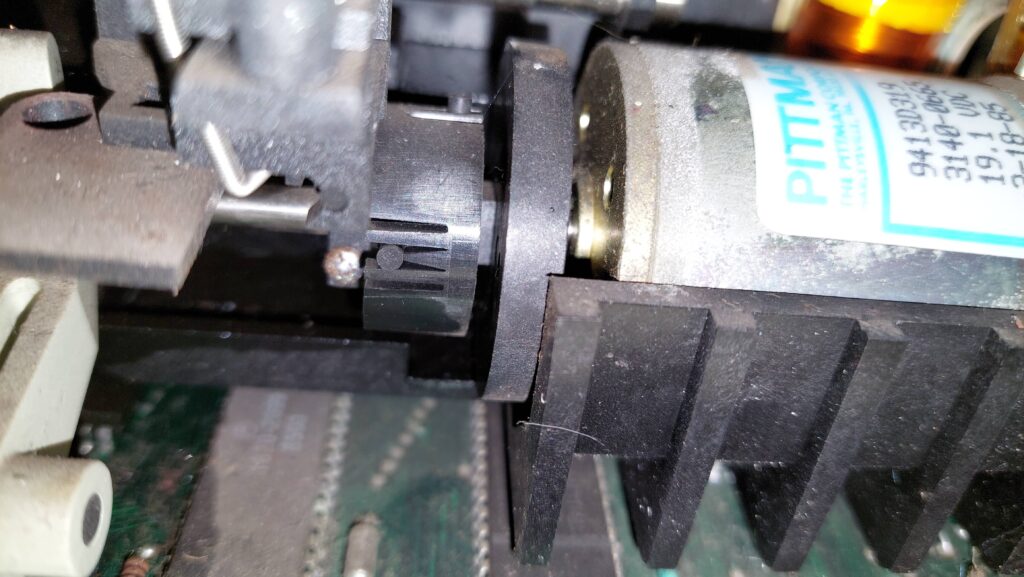

The paper motor has a flexible coupling like a universal joint. Once the axle clamp is backed-off the motor can be removed. Then the solenoid can be disconnected and removed. The core just falls out.

The carriage guide can then be removed and then the carriage from the guide. The guide cleaned up very easily with some emery paper. Often rust looks much worse than it is, and it was certainly the case this time.

I didn’t fully disassemble the carriage. There are a couple of springs in there, so i just put the carriage in a takeaway container and sealed it down.

The main plastic chassis could then be unscrewed and removed.

After the springs were removed, the paper release mechanism came away fairly easily. Then the bearings could be released.

The bearings seemed to have seized but they turned out to be ok. They had just got a little glued with rust from the shaft. They are probably stainless steel.

I removed the rest of the “grip” from the wheels and wrapped them in some emery paper. We’ll see how that lasts. I could have cut it a little straighter, but i thought it was good enough against a rubber wheel.

I didn’t touch the mains wiring. It looked well protected. I did give the board a clean in spots, but i didn’t want to get any moisture into the buttons.

The button panel is aluminium and it had some oxidation. I just gave it a light rub with some scotchbrite.

Unassembled, the plotter took up a lot of space:

The case was filthy. I used jif and elbow grease to clean it up.

Having cleaned everything, and made sure that everything was moving ok, i put it all back together. I put a drop of oil on the carriage guide.

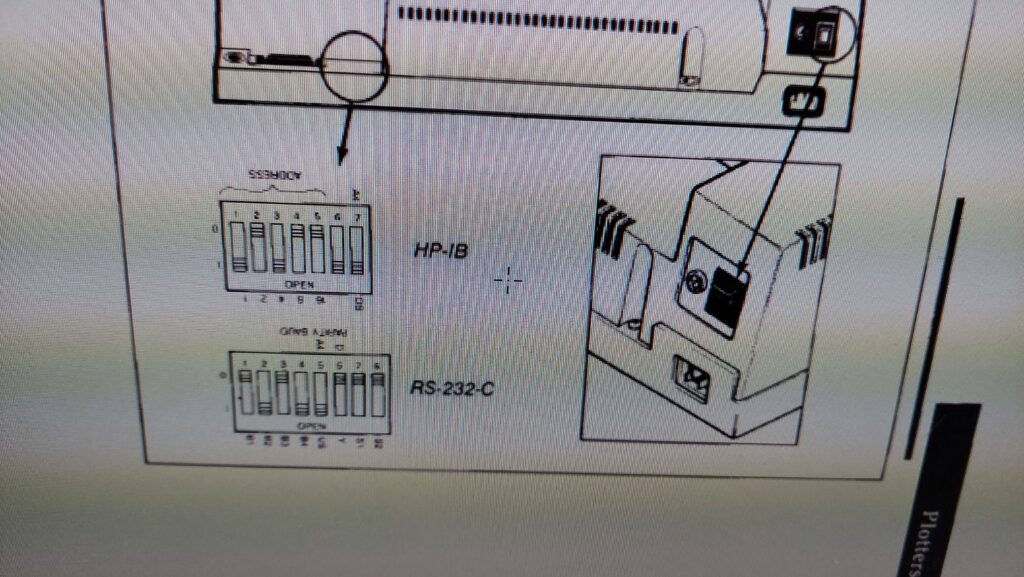

I set the DIP switches as per the manual, except i used A4.

The HP 150 had been set up to use the serial plotter. I changed this with the configuration program on the setup disk to HP-IB address=05.

Initially, the grip on the paper failed at the flat spots on the rubber wheels. I rounded them off with a file and then added some surgical tubing over them. They worked much better then.

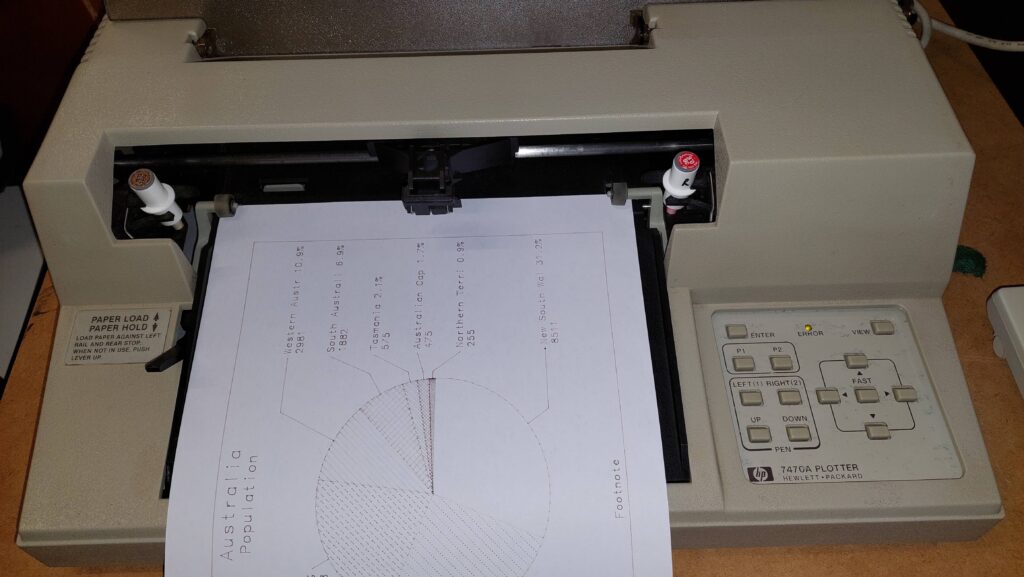

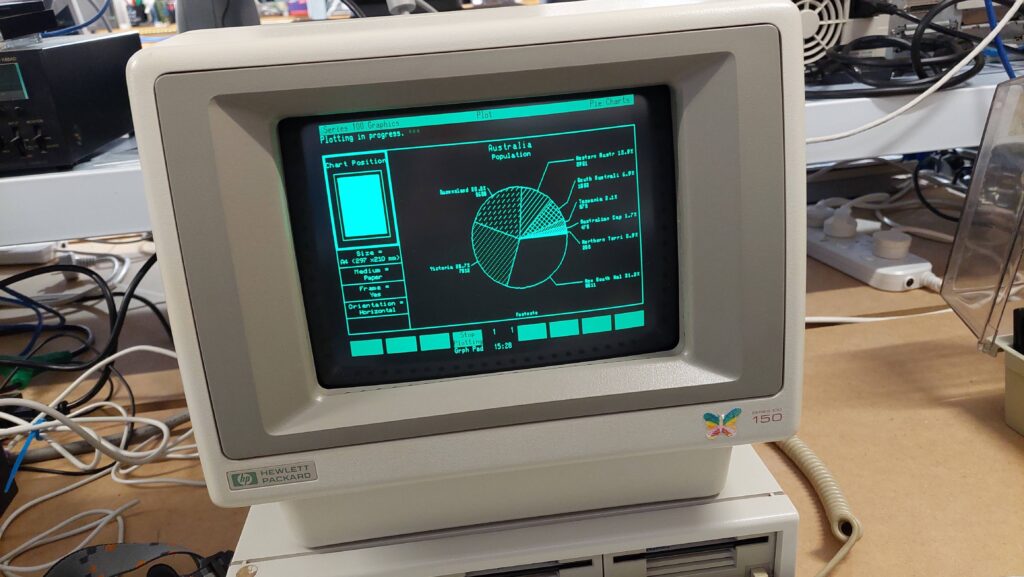

The plot was produced with the Pie Chart software. The paper size has to be set correctly, otherwise the program complains that the plotter is not compatible.

Happy days. I’ll try it out on the HP 85 when i get a moment.

There were about 30 happy days before a fault developed in the carriage servo. This sent the carriage careering into the end-stop where it halted abruptly and blew the fuse.

Unfortunately, i could not resolve this issue. It appears to be in one of the gate arrays, so i won’t be able to resolve this unless a “spares machine” appears – either serial or HP-IB.

At least it got one last chance to perform before departing this mortal coil!