I had two unallocated NEC FD1165 8″ Floppy Disk Drives. This is a half height unit that uses 24V for the spindle motor.

The heads on this unit are easy to access once the drive cover is removed. Annoyingly, the configuration links are on the reverse side.

This unit, in its standard configuration, refused to release the door latch which was a little inconvenient. I changed a solder link so that it was more willing – “in use”.

Section 2.8 of the maintenance manual:

| Function | Label | Position | Setting |

| Drive Identification | DX | 1 | Device select 1 (first device select) – Drive A: |

| Head Load | HL | 2 | Head loads with device select |

| Radial Ready Jumper | RX | 1 | Ready Gated by Drive Select |

| Side Select Jumper | SS | 1 | Use side select signal |

| Write Protect Jumper | PR | 1 | Send write protect and enforces write protect |

| Door Lock | DL | 2 | HL.DSX + DLH DLH= Door Lock Hold |

| DR | 2 | ||

| DH | 2 | ||

| In Use (Solder) | IU | 2 | |

| Read Data | RD | 1 | Enable read data |

| Busy Lamp Indicators | BU | 1 | |

| BS | 2 | Weird setup! | |

| T1 | Installed | Prevent rapid head load/unload |

One of the two drives (let’s call it drive one) had been dropped at some point in its life. There are some significant dents in the chassis and the top head was initially at an unexpected angle.

I repaired this when I was imaging the 8” disk collection, and the drive operated quite well during that exercise.

The second floppy disk drive was not reliable when I had previously attempted to use it but i had not investigated further.

I used the first unit to create system disks and these disks worked well.

While loading software on to the hard disk using the first unit, I noticed that some disks which had been successfully imaged with unit one were not being read by the system using the same unit one. Of course, the processing done by the greaseweazle is quite different from that done by a real floppy disk drive controller, so the performance is not necessarily the same.

I imaged my configured boot disk using greaseweazle with unit one. Drive two was swapped into the system. It did not work with the original disk or with a new disk written by drive one.

Drive two did boot if i wrote the disk using drive two. This suggested that the alignment of the two drives was different.

The second drive was able to read some of the disks that the first drive could not, but not all.

What followed was several days of frustration, which left me with the impression that these drives (in combination with the floppy disk controller and ancient floppy disks) are not quite at the peak of their performance.

I initially used just ImageDisk to align the drives. This is a little tricky because I have no reliable double-sided reference disks. I do have a reliable single sided reference disk. For the second side I checked alignment using disks that had been written back in the golden age when the writing drive was in its prime. I checked with several disks which may or may not have been written with different drives!

The drives were not optimum. I’m sure I aligned the first drive prior to imaging, but its possible the alignment has shifted (my shed temperature has dropped significantly). I adjusted the drives as best I could. Using the Microsoft Multiplan disk, the drives seemed solid from track 0 to track 76.

Changing to some other disks (with a smaller number of sectors) the performance seemed less consistent with marked variation between tracks. Adjusting the bottom head involves moving the stepper motor baseplate – three screws loosened and then using a screwdriver to muscle the baseplate in or out, noting that the tracks have about a 0.5mm spacing. Often drives have a mechanism that convert quite large adjustment to effect a small change in position. Not this one. It requires a very gentle touch to get it in the optimum position.

As for most drives, the top head is adjusted relative to the bottom head. It requires even more patience because it is mounted using two screws which, once released, allow a lot of movement over a 3mm x 3mm plane and a wide range of angles. Extreme patience is required. The maintenance manual doesn’t even describe this operation – recommending replacement of the carriage instead. Nevertheless, it is possible to manoeuvre the head into a good position. Both drives required adjustment.

Unfortunately, the PC disk controller was too sensitive (two easily satisfied), so i could not get the alignment quite right for the actual system, which is fussy. I still had trouble reading original disks.

I then turned to instrumentation. I used the test points (8/9) and an oscilloscope in differential mode to get some additional info – the magnitude of the signal. This is at the output of what may be a custom amplifier. As was clear during the imaging of the 8” disk collection, performance declines with track number. The signal to noise ratio is significantly worse on the inner tracks, even when optimum. It was also clear that the magnitude was not steady.

I also happened to have an SA 120 alignment disk, which is very good for aligning the bottom head, but not the top head. It’s single sided!

The test signal is at Track 38. 100mV/div. 20ms/div. It is the gold standard, but may be less than optimum for the disks if they have been written out of alignment. There may also be a better compromise position if the top head is just a little out.

The whole concept of reducing the write current on, what are smaller sectors, seems to be a solution fraught with peril. Maybe they should have stopped at 60 tracks. I’ve noticed repeatedly that failures are likely on these inner tracks.

Having used this method the second drive was pretty good but the first drive is still unreliable.

Along the way I found a few things:

- When I configured the boot disk I added the card boot files to a disk that was close to full, so they got written to the inner tracks.

- I found that on occasions the boot process gave up on the floppy disk and went looking for the files on other drives eg the scsi2sd drive. This eventually led me to find that the floppy disk only needs to contain osload.com. No boot tracks are required. Osload is happy to load the card boot files from E:, after which E: becomes the system disks. For whatever the reason, the ROM can find Osload on the floppy but not on the scsi2sd.

- If the drive is configured as drive 2 (second device select) it still boots but the drive is B:.

I had one more try at the first drive. I spent a lot of time making sure that the alignment gave the same amplitude for both heads. I checked it with a disk written by the second drive. It was not identical, but it was pretty good. But still it would not boot from disks written by the other drive.

In desperation, I thought I would just try aligning the bottom head (and hopefully the top head with it) by nudging and trying to boot. Eventually a found the correct position. It was not a big change but it was definitely different from where I had it. So, in a boil over, the correct position is not where the maximum amplitude is – unless, of course, something moved.

I noticed discrepancies between the two drives, so I tried a new alignment technique. Noting that problems are exaggerated on the inner tracks, I used greaseweazle to read just the inner tracks. The Disks were written with the second drive and read back with the first drive. By adjusting the carriage alignment in very small steps and then reading back it was possible to improve the alignment until bad sectors were not read.

This proved to be quite effective. Although the alignment was good, it is simply the case that the first drive does not read as well as the first. One disk would not boot on the first drive, but would on the second. Reading with greaseweazle with either drive was fine – even with only one rev. Once the disk was written with the first drive it would boot on either.

Along the way I noticed that the floppy disk controller card offers some options wrt precompensation. There are some links on the card. I have no idea whether the settings are correct for the drive. No doco. No mention of precompensation in the drive manual.

I think I now have two drives that a reasonably aligned. I have loaded a lot of software off a variety of disks using the second drive. No doubt the alignment of the two is imperfect. The second drive seems to perform better – perhaps it is better aligned, but I think its read circuit just performs a little better.

Greaseweazle/HxC perform better than the physical drive controller. I guess that’s the advantage of processing power and the ability to post-process but i have had the converse as well eg the Sorcerer with the Micropolis controller.

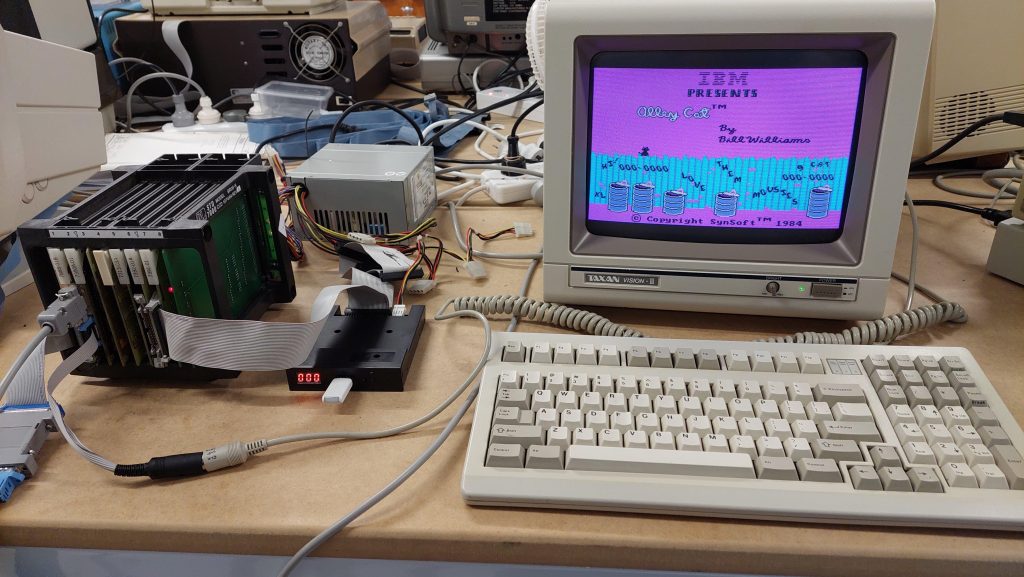

I’ve used the second drive in the unit.