It was a very long time (about three years) before I mustered the courage to tackle the CRT. My assessment of the implosion risk is that it is credible, and therefore should be treated with some caution.

I started by making a box to secure the CRT while I did the work. I then removed the CRT from the unit and mounted in the box. This protected it from the rough treatment that it was about to receive, and it would help contain material in the event of a mishap.

I’ve seen several approaches on youtube to cataract remediation. Some people heat up the tube to quite high temperatures, which just looks too dangerous to me due to the significant possibility of uneven heating causing catastrophic failure. See:

https://www.videokarma.org/archive/index.php/t-184752.html

Others use a hot wire, which seems more reasonable. I thought about cutting through with a high strength fishing line.

In the end I found the gel was quite soft and could be worked out with some plastic picnic knives. It took a couple of hours and several broken knives to get it to a point where i could break the suction without risking the glass.

I expect the second layer of glass protected the CRT from user abuse, and perhaps gave some assurance that if the screen suddenly imploded, the user had some protection. I’m not totally convinced that the glass itself provided a lot of protection because it isn’t very thick, but it may be laminated. It does have a nice non-reflective surface though.

I think the gel was probably doing two things. Firstly, it attached the protective low sheen glass cover without any risk of dust between the two layers. I expect it was also part of the protection of the CRT from the user and vice versa. It would have been effective at absorbing energy and reducing the scattering of the front glass. Something akin to an air-bag.

I cannot think of a way to replace the gel, but i can at least replace the antiglare screen.

There is no such protection at the back of the CRT, so once the computer cover is off the risk is probably higher at the back than the front.

The CRT also has an anti-implosion band which was in good condition and i left it as it was.

After cleaning up the glass, I reattached the antiglare screen with double-sided tape. Once in the machine, the anti-glare screen is against the enclosure. I will be treating the machine with some respect when moving it around.

Before putting the tube back in the machine, i put tape around the gap to seal it from dust.

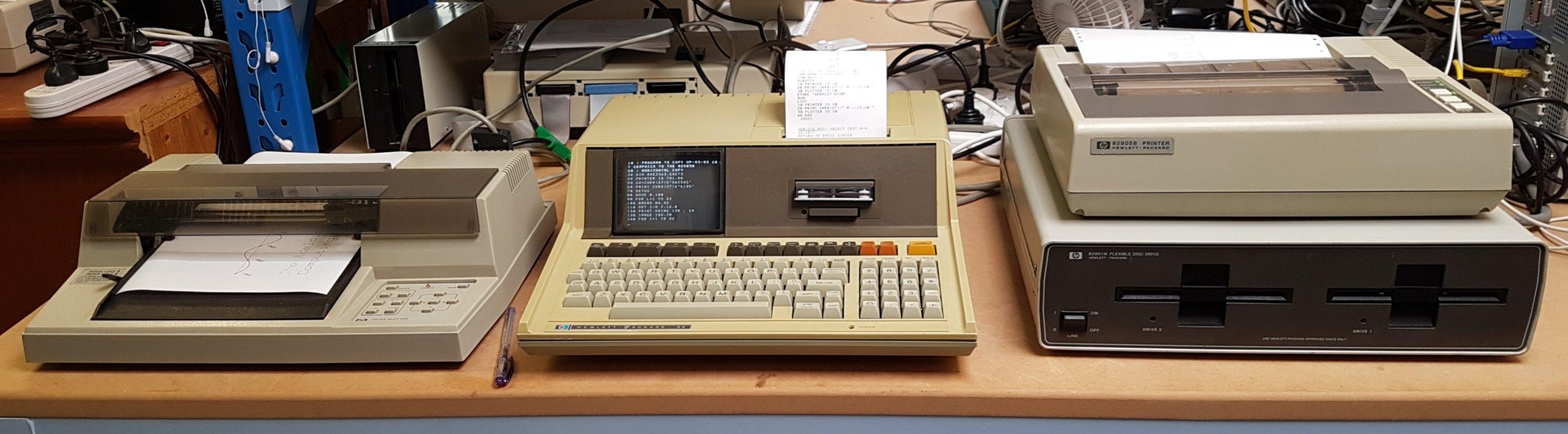

Before and after: